The Bulk Material Loading Bellows is a flexible and extendable fabric sleeve that connects bulk material storage equipment (such as cement silos or grain bins) to transport vehicles (such as trucks, railcars, or ships). During bulk loading operations, it creates a sealed channel for material flow and flexibly adjusts its length according to working conditions.

Structural Components of the Bulk Material Loading Bellows

Loading Bellows Body

- Manufacturers usually construct the spout body from multiple materials with different properties, such as wear-resistant synthetic fibers (e.g., polyester or polypropylene) or high-strength coated fabrics. These materials provide excellent abrasion resistance, corrosion resistance, and flexibility, enabling the spout to adapt to various conveying requirements.

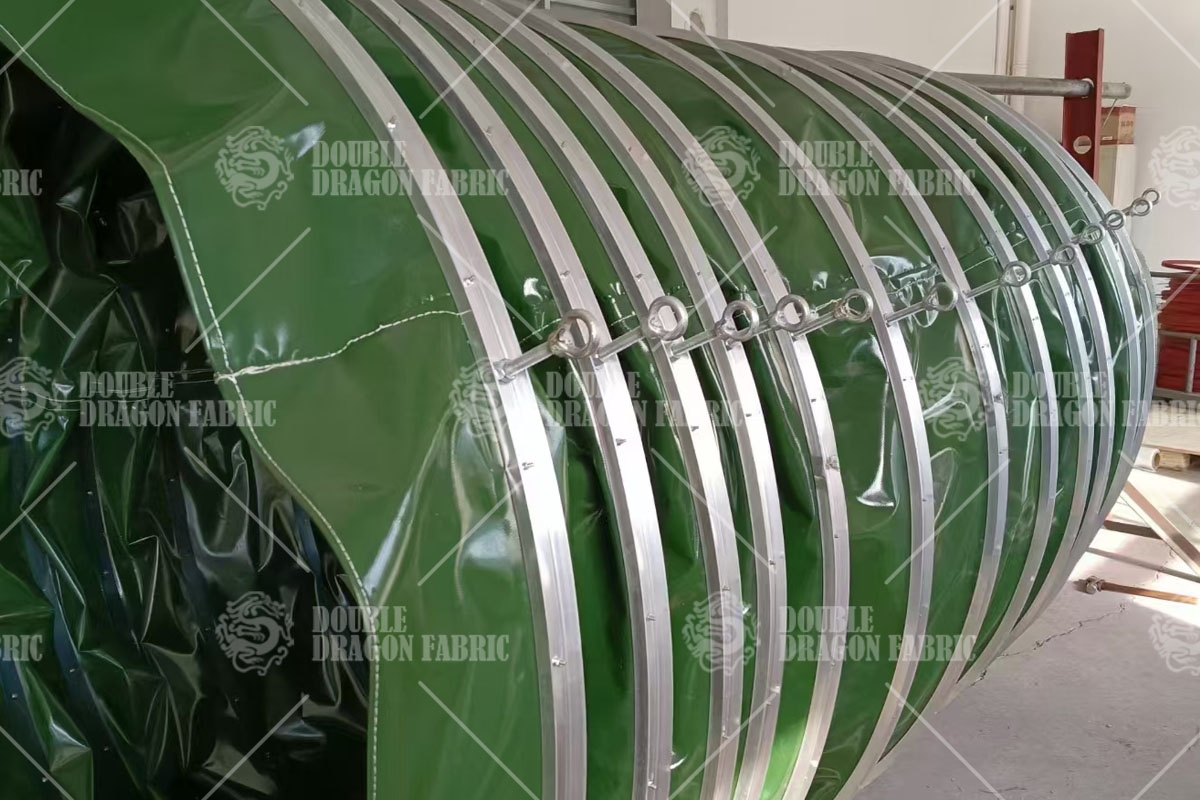

Supporting Frame

- To maintain the spout’s shape and strength during extension and retraction, engineers install a metal frame inside the structure. Common options include steel wire or aluminum alloy frameworks. The frame adopts a foldable or telescopic design, allowing it to expand and contract smoothly along with the fabric body.

Connection Components

- The upper connector links the spout to the discharge outlet of the bulk loader, while the lower connector attaches to the inlet of the transport vehicle. Designers typically adopt sealed connection methods, such as flange joints or clamp fittings, to prevent material leakage during transfer and ensure efficient operation.

Loading Bellows :Key Features

- High Flexibility and Adjustable Length : The telescopic design enables operators to adjust the spout’s length easily, accommodating varying vehicle heights and positions during loading or unloading. As a result, it eliminates the need to move the loading machine frequently, improving operational efficiency.

- Flexible Connection : The soft and elastic structure absorbs impact forces generated by falling materials, reducing wear and damage to both materials and equipment. It also adapts to minor displacement and vibration, maintaining a secure and stable connection throughout the process.

- Excellent Sealing Performance : With a tight sealing design, the spout prevents dust escape and material leakage, thereby reducing waste and minimizing environmental pollution. This feature is particularly critical when handling toxic, hazardous, or fine-powder materials.

- Strong Resistance to Wear and Corrosion : Because the spout handles various bulk materials such as cement, minerals, and grains, its fabric resists friction and impact effectively. When conveying corrosive materials, the surface coatings provide additional chemical resistance, significantly extending service life.

Bulk Material Loading Bellows :Applications

- Building Materials Industry : Operators use Bulk Material Loading Bellows extensively in the bulk handling of cement, lime powder, and slag powder. The system transfers materials from silos or grinding stations to mixing plants and construction-site vehicles.

- Grain Industry : In grain handling, the spout loads and unloads bulk materials such as wheat, corn, and rice, efficiently transferring them from silos to trucks or ships.

- Chemical Industry : Chemical plants apply the spout to transfer fertilizers and raw materials, ensuring safe and sealed bulk transport throughout the storage and production process.

- Power Industry : Power stations employ Bulk Material Loading Bellows to convey coal, limestone, and desulfurization agents, improving efficiency in fuel handling and emission control.

Conclusion

The Bulk Material Loading Bellows combines wear resistance, high-temperature tolerance, and corrosion resistance to achieve sealed and flexible bulk material transport. By relying on its elastic, retractable structure, it prevents dust emission and environmental pollution during loading and unloading operations.

Today, industries such as cement production, grain processing, and port logistics widely use this equipment for solid powder handling, packaging, and recovery. It also serves effectively in industrial dust collection and discharge systems, promoting cleaner and safer material management.